Magnetohydrodynamic and Electrochemical Phenomena in Remelting Processes

In order to decrease CO2 production, the developments of a new generation of metallurgical processes using electric currents are planned by the world leading industrial groups. Strong currents will be transferred through plasma and high temperature electrolytes to achieve the production of new metallic alloys. The fundamental knowledge built by our research has the potential to solve complex physical, technical, and design issues that can arise during these crucial developments.

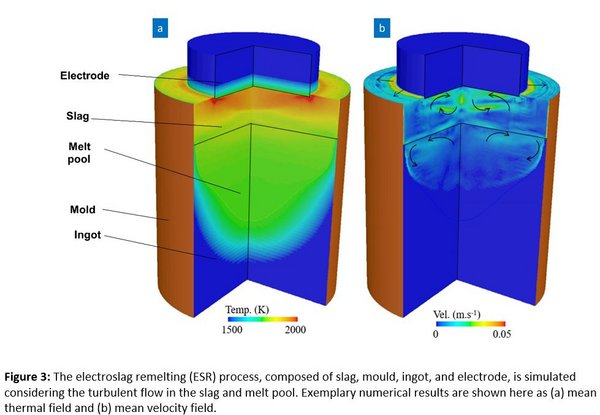

From daily experience, we know that. with a strong electric current, materials can be heated and even melted. However, when applied on an industrial scale, the fact that most materials are opaque causes a major problem because important details on what happens remain hidden. Here, the numerical process simulation acts as visualiser and allows to zoom-in when necessary. Even simulations with hypothetic properties or unusual process conditions can be done and thus hints in which direction a process optimisation might be possible can be gained. As an example, we have worked on understanding and optimising the Electro-slag remelting (ESR) process. This is a process where an extremely high electric current heats a liquid slag that then melts an electrode so that the alloy is then drop-wise crossing the liquid slag and forming a new liquid pool that finally solidifies with an improved quality.

The corresponding aims and objectives of this research field are:

- to understand the interaction between phase distribution and magnetohydrodynamics when strong electric currents are applied;

- to predict the electrical current path in the presence of strong spatial and temporal variation of electric conductivity;

- to solve process instabilities and predict the formation of defects in the electroslag remelting process (ESR) and vacuum arc remelting (VAR) process;

- to understand electrochemical aspects of the ESR process;

- to predict the thermal and solidification characteristics during remelting of different metallic alloys;

- to explore the origin of the coherent arc behaviour in the VAR process;

- building a numerical model to predict the behaviour of an electric arc inside a furnace accounting for magnetohydrodynamics, flow dynamics, compressibility, turbulence and thermal fields.

Examples of recent achievements are given in Fig. 3. Further details on that research field can be found in

- Karimi-Sibaki E., Vakhrushev A., Kadylnykova A., Wu M., Ludwig A., Bohacek J.: Electrochemistry Communications 155 (2023) 107567 DOI: doi.org/10.1016/j.elecom.2023.107567

"A multiphase model for exploring electrochemical Marangoni flow" - Karimi-Sibaki E., Vakhrushev A., Wu M., Ludwig A., Bohacek J., Kharicha A.: Journal of The Electrochemical Society (2023) 170 072501 DOI: doi.org/10.1149/1945-7111/ace133

"Transient Simulation of Diffusion-Limited Electrodeposition Using Volume of Fluid (VOF) Method" - Zhang H., Wu M., Rodrigues C.M.G, Ludwig A., Kharicha A., Rónaföldi A., Roòsz A., Veres Z., Sveda M.: Acta Materialia 241 (2022) DOI: doi.org/10.1016/j.actamat.2022.118391

"Dendrite fragmentation mechanism under forced convection condition by rotating magnetic field during unidirectional solidification of AlSi7 alloy" - Karimi-Sibaki E., Peyha M., Vakhrushev A., Wu M., Ludwig A., Bohacek J., Preiss B., Kharicha A.: Scient. Rep. (2022) DOI: doi.org/10.1038/s41598-022-24595-7

"Experimental and numerical investigations of arc plasma expansion in an industrial vacuum arc remelting (VAR) process" - Karimi-Sibaki E., Kharicha A., Vakhrushev A., Abdi M., Wu M., Ludwig A., Bohacek J., Preiss B.: J. Mater. Res. Techn. 19 (2022) 183-193. DOI:doi.org/10.1016/j.jmrt.2022.05.036

"Numerical modeling and experimental validation of the effect of arc distribution on the as-solidified Ti64 ingot in vacuum arc remelting (VAR) process" - Kharicha A., Al-Nasser M., Barati H., Karimi-Sibaki E., Vakhrushev A., Abdi M., Ludwig A., Wu M.: European J. Mech. B Fluids (2022) 90-105. DOI: doi.org/10.1016/j.euromechflu.2022.02.001

"Tornados and cyclones driven by Magneto-hydrodynamic forces" - Karimi-Sibaki E., Kharicha A., Vakhrushev A., Wu M., Ludwig A., Bohacek J.: J. Iron Steel Res. Int. (2021). DOI:10.1007/s42243-021-00686-z

"Investigation of effect of electrode polarity on electrochemistry and magnetohydrodynamicsusing tertiary curent distribution in electroslag remelting process" - Al-Nasser M., Kharicha A., Barati H., Pichler C., Hackl G., Gruber M., Ishmurzin A., Redl C., Wu M., Ludwig A.: Metals 11 (2021) 1482 1-17. DOI: 10.3390/met11091482

"Toward a Simplified Arc Impingement Model in a Direct-Current Electric Arc Furnace" - Karimi-Sibaki E., Kharicha A., Abdi M., Vakhrushev A., Wu M., Ludwig A., Bohacek J.: Metall. Mater. Trans. B (2021). DOI: 10/1007/s11663-021-02264-w

"A Numerical Study on the Influence of an Axial Magnetic Field (AMF) on Vacuum Arc Remelting(VAR) Process" - Kharicha A., Karimi-Sibaki E., Vakhrushev A., Wu M., Ludwig A., Bohacek J.: Int. J. Heat and Mass Trans. (2021). DOI: 10.1007/s00231-021-03071-4

"Hydrodynamically enhanced electrochemical mass transferon the surface of an electrically conductive dropet" - Karimi-Sibaki E., Kharicha A., Wu M., Ludwig A., Bohacek J.: Metall. Mater. Trans. B 51 (2020) 871-879. DOI: 10.1007/s11663-020-01795-y

"A Numerical Investigation on the Electrochemical Behavior of CaO and Al 2O 3 in the ESR Slags" - Chaulet J., Kharicha A., Charmond S., Dussoubs B., Hans S., Wu M., Ludwig A., Jardy A.: Metals 10 (2020) 490:1-16. DOI: 10.3390/met10040490

"A 2D Multiphase Model of Drop Behavior during Electroslag Remelting" - Karimi-Sibaki E., Kharicha A., Vakhrushev A., Wu M., Ludwig A., Bohacek J.: Electrochem. Comm. 112 (2020) 106675. DOI: 10.1016/j.elecom.2020.106675

"A volume of fluid (VOF) method to model shape change during electrodeposition" - Karimi-Sibaki E., Kharicha A., Wu M., Ludwig A., Bohacek J.: Metall. Mater. Trans. B 51 (2020) 222-235. DOI:10.1007/s11663-019-01719-5

"A Parametric Study of the Vacuum Arc Remelting (VAR) Process: Effects of Arc Radius, Side-Arcing, and Gas Cooling" - Karimi-Sibaki E., Kharicha A., Wu M., Ludwig A., Bohacek J.: J. Electroch. Soc., 165 (2018) E604-E615. DOI:10.1149/2.1201811jes

"Contribution of an Electro-Vortex Flow to Primary, Secondary and Tertiary Electric Current Distribution in an Electrolyte" - Karimi-Sibaki E., Kharicha A., Wu M., Ludwig A., Bohacek J.: Ionics 24 (2018) 2157-2165. DOI: 10.1007/s11581-018-2460-3

"Confrontation of the Ohmic approach for with the ionic transport approach for modeling the electrical behavior of an electrolyte" - Karimi-Sibaki E., Kharicha A., Wu M., Ludwig A., Bohacek J.: Appl. Math. 357 (2018) 357-373. DOI: 10.1016/j.amc.2018.01.008

"Modeling electrochemical transport of ions in the molten CaF2 –FeO slag operating under a DC voltage" - Kharicha A., Karimi-Sibaki E., Wu M., Ludwig A., Bohacek J.: Steel Res. Int. 89 (2018) 1700100 1-20. D OI: 10.1002/srin.201700100

"Review on Modeling and Simulation of Electroslag Remelting" - Karimi-Sibaki E., Kharicha A., Wu M., Ludwig A., Bohacek J.: Steel Res. Int. 88 No. 5 (2017) 1700011 (1-8).

"Toward Modeling of Electrochemical Reactions during Electroslag Remelting (ESR) Process" - Kharicha A, Wu M., Ludwig A., Karimi-Sibaki: Metall. Mater. Trans. B, 47 (2016) 1427-34.

"Simulation of the Electrical Signal During the Formation and Departure of Droplets in the Electro Slag Remelting Process" - Karimi-Sibaki E., Kharicha A., Bohacek J., Wu M., Ludwig A.: Adv. Eng. Mater. 18 (2016) 224-30.

"On Validity of Axisymmetric Assumption for Modeling an Industrial Scale Electroslag Remelting Process" - Karimi-Sibaki E., Kharicha A., Bohacek J., Wu M., Ludwig A.: Metall. Mater. Trans. B, 46 (2015) 2049-2061.

"A Dynamic Mesh-Based Approach to Model Melting and Shape of an ESR Electrode"

see also our Topic Related Publications