Nozzle Clogging in Steelmaking Processes

Although it was named “continuous”, the steel continuous casting is not always run smoothly without being disturbed. Due to this or that reasons, e.g. chemical reactions between submerged entry nozzle (SEN) refractory and steel melt, deposition of non-metallic inclusions on the SEN wall etc., the passage of the SEN becomes narrowed. Sooner or later, it must be replaced by a fresh one as it gets clogged. This so-called clogging phenomenon is a major problem for the steel industry.

The modeling activity has the potential to minimize the clogging tendency by optimizing the casting parameters. It will also become a part of the industry 4.0 as an important tool for virtual/intelligent manufacturing. The developed numerical model can also be extended to investigate the clogging/fouling phenomenon (deposition and accumulation of solid suspended particles on the fluid passage) in other engineering processes, such as in heat exchangers, petrochemical industry, automotive industry food production, and pharmaceutical industries.

The corresponding aims and objectives of this research field are:

- to develop a transient clogging model considering key physical/chemistry mechanisms: - origin of the non-metallic inclusions (NMIs); - transport of NMIs by the molten steel of high turbulence, and the effect of Ar gas; - behaviour of NMIs in the boundary layer of the nozzle wall (refractory); - adhesion mechanism of NMIs on the nozzle wall and the effect of nozzle refractory materials; - growth of the clog front and its interaction with the turbulent melt flow; - flow and possible solidification of molten steel in the clog region; - fragmentation/detachment of the clog.

- evaluation of the numerical model against available laboratory/industry experiments;

- achievement of a fundamental understanding about the nozzle clogging in steelmaking processes, and aid the industry to optimize the process parameters.

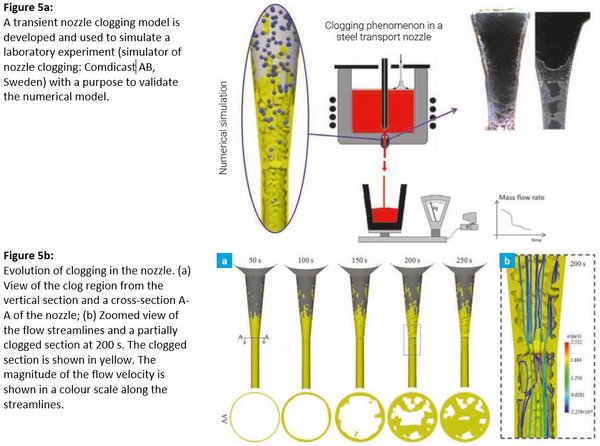

Examples of recent achievements are given in Fig. 5. Further details on that research field can be found in

- Barati H., Wu M., Ilie S., Kharicha A., Ludwig A.: Powder Technology 434 (2024) DOI: doi.org/10.1016/j.powtec.2023.119307

"Numerical modeling of clog fragmentation during SEN clogging in steel continuous casting" - Barati H., Wu M., Michelic S., Ilie S., Kharicha A., Ludwig A., Kang Y.: Metall. Mater. Trans B. 52 (2021) 4167-4178. DOI: 10.1007/s11663-021-02336-x

"Mathematical Modeling of the Early Stage of Clogging of the SEN During Continuous Casting of Ti-ULC Steel" - Barati H., Wu M., Kharicha A., Ludwig A.: Steel Research int. 91 (2020) 2000230. DOI: 10.1002/srin.202000230

"Role of Solidification in Submerged Entry Nozzle Clogging During Continuous Casting of Steel" - Barati H., Kharicha A., Wu M., Ludwig A.: Metall. Mater. Trans. B 50 (2019) 1428-1443. DOI: 10.1007/s11663-019-01551-x

"Calculation Accuracy and Efficiency of a Transient Model for Submerged Entry Nozzle Clogging" - Wu M., Barati H., Kharicha A., Ludwig A.: 8th Int. Conf. on Mod. & Simul. of Metall. Processes in Steelmaking (STEELSIM2019), Toronto, Canada (2019) pp. 664-667 DOI: 10.33313/503/069

"Using a numerical model to study the transient clogging phenomena in SEN during continuous casting of steel" - Barati H., Wu M., Kharicha A., Ludwig A.: Powder Technology 329 (2018) 181–198. DOI: 10.1016/j.powtec.2018.01.053

"A transient model for nozzle clogging" - Barati H., Wu M., Kharicha A., Ludwig A.: 7th Int. Conf. Solidification and Gravity (SG 2018), Miskolc, Hungary, pp. 144-149.

"Discussion on possible solidification during SEN clogging in steel continuous casting" - Barati H., Wu M., Holzmann T., Kharicha A., Ludwig A.: in "CFD Modeling and Simulation in Materials Processing 2018", ISBN: 978-3-319-72059-3, Eds. Nastac L. et al. Springer, Cham, (2018) 149-158. DOI: 10.1007/978-3-319-72059-3_15

"Simulation of Non-metallic Inclusion Deposition and Cloggin of Nozzle" - Barati H., Wu M., Kharicha A., Ludwig A.: IOP Conf. Series: Materials Science and Engineering (LMPC-15) 143 (2016) 012026.

"Assessment of Different Turbulence Models for the Motion of Non-metallic Inclusion in Induction Crucible Furnace"

see also our Topic Related Publications