Steel Continous Casting: Solidification, Flow and Magnetohydrodynamics

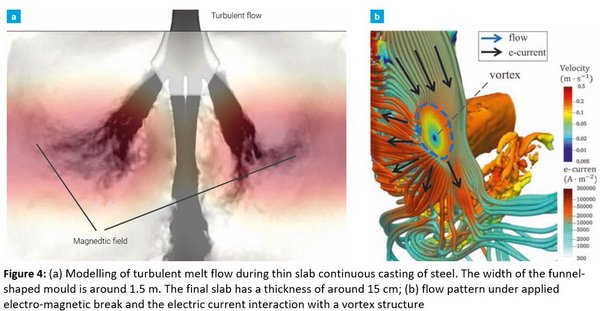

For more than three decades numerical simulations of steel continuous casting considering solidification and flow are widely spread. They are valuable for the design and optimization of the casting process, especially for thin slab casting (TSC). Interaction between flow and solidification, which is quite intensive in TSC, and electromagnetic braking used to stabilise the flow are up-to-date topics where numerical models are recently under development. In both fields, we have obtained successful developments that are now applied under productive conditions.

Our scientific investigations provide the theoretical basis for innovative control techniques which will lead to growing productions rates by increasing the casting speed while keeping the quality. Thus, large energy savings by casting at lower super heat and promoting CO2 reduction will be achieved. The methodology developed opens the possibility to apply electromagnetic fields to other metallurgical and semiconductor industries.

The corresponding aims and objectives of this research field are:

- multiphase phenomena modelling during continuous casting (CC): turbulent flow, shell growth, non-metallic inclusions (NMI) and bubbles motion, meniscus behaviour, etc.;

- model development of the turbulent flow under the applied magnetic field considering the Lorentz force;

- coupled numerical simulation of the solidification during CC with the magnetohydrodynamic (MHD) effects from the electromagnetic brake (EMBr);

- models’ verification against analytical solutions, experimental data and existing numerical results;

- influence of the casting and EMBr conditions on the CC mould flow pattern, the shell thickness, meniscus temperature, slag band stability, and NMI removal efficiency;

- application of the results of the numerical studies for a real industrial process with optimization aims regarding the cast products quality.

Examples of recent achievements are given in Fig. 4. Further details on that research field can be found in

- Vakhrushev A., Karimi-Sibaki E., Wu M., Tang Y., Hackl G., Watzinger J., Bohacek J., Kharicha A.: Eurotherm 2024 - Journal of Physics: Conference Series 2766 (2024) 012196 DOI: doi:10.1088/1742-6596/2766/1/012196

"Effects of the asymmetric and oscillating turbulent melt flow on the heat transfer and solidification inside the thin slab continuous casting (TSC) mold under the applied electromagnetic brake (EMBr)" - Vakhrushev A., Karimi-Sibaki E., Bohacek J., Wu M., Ludwig A., tang Y., Hackl G., Nitzl G., Watzinger J., Kahricha A.: Metals 13 (2023) DOI: doi.org/10.3390/met13030444

"Impact of Submerged Entry Nozzle (SEN) Immersion Depth on Meniscus Flow in Continuous Casting Mold under Electromagnetic Brake (EMBr)" - Zhang Z., Wu M., Zhang H., Ludwig A., Kharicha A.: Steel Research int. (2022). DOI: 10.1002/srin.202200065

"The Role of Mold Electromagnetic Stirring in the Dissipation of Superheat during the Continuous Casting of Billets" - Zhang H., Wu M., Zhang Z., Ludwig A., Kharicha A., Ronaföldi A., Roosz A., Veres Z., Sveda M.: Metall. Mater. Trans. B (2022). DOI: doi.org/10.1007/s11663-022-02516-3

"Experimental Evaluation of MHD Modeling of EMS During Continuous Casting" - Vakhrushev A., Kharicha A., Karimi-Sibaki E., Wu M., Ludwig A., Nitzl G., Tang Y., Hackl G., Watzinger J.: Steel Research int. (2022). DOI:doi10.1002/srin.202200088

"Modeling Asymmetric Flow in the Thin-Slab Casting Mold Under Electromagnetic Brake" - Vakhrushev A., Kharicha A., Wu M., Ludwig A., Nitzl G., tang Y., Hackl G., Watzinger J., Rodrigues C.M.G.: J. Iron Steel Res. Int. 29 (2022) 88-102. DOI: doi.org/10.1007/s42243-021-00734-8

"Norton Hoff model for deformation of growing solid shell of thin slab casting in funnel-shape mold" - Kharicha A., Vakhrushev A., Karimi-Sibaki E., Wu M., Ludwig A.: Phys. Rev. Fluids 6 (2021). DOI: 10.1103/PhysRevFluids.6.123701

"Reverse flows and flattening of a submerged jet under the action of a transverse magnetic field" - Zhang Z., Wu M., Zhang H., Hahn S., Wimmer F., Ludwig A., Kharicha A.: J. Mat. Proc. Tech. 301 (2022). DOI: 10.1016/j.jmatprotec.2021.117434

"Modeling of the as-cast structure and macrosegregation in the continuous casting of a steel billet: Effect of M-EMS" - Vakhrushev A., Kharicha A., Wu M., Ludwig A., Tang Y., Hackl G., Nitzl G., Watzinger J., Bohacek J.: Metals 11 (2021) 1375 1-20. DOI: 10.3390/met11091375

"On Modelling Parasitic Solidification Due to Heat Loss at Submerged Entry Nozzle Region of Continuous Casting Mold" - Vakhrushev A., Kharicha A., Karimi-Sibaki E., Wu M., Ludwig A., Nitzl G., Tang Y., Hackl G., Watzinger J., Eckert S.: Metall. Mater. Trans. B (2021). DOI: 10.1007/511663-021-02247-x

"Generation of Reverse Meniscus Flow by Applying An Electromagnetic Brake" - Vakhrushev A., Kahricha A., Liu Z., Wu M., Ludwig A., Nitzl G. tang Y., Hackl G., Watzinger J.: Metall. Mater. Trans. B (2020) 2811-2828. DOI:10.1007/s11663-020-01952-3

"Electric Current Distribution During Electromagnetic Braking in Continuous Casting" - Liu Z., Vakhrushev A., Wu M., Kharicha A., Ludwig A., Li B.: Metall. Mater. Trans. B 50 (2019) 543-554. DOI: 10.1007/s11663-018-1443-0

"Scale-Adaptive Simulation of Transient Two-Phase Flow in Continuous-Casting Mold" - Liu Z., Li B., Vakhrushev A., Wu M., Ludwig A.: Steel Research int. 90 (2019) 18020117 1-10. DOI: 10.1002/srin.201800117

"Physical and Numerical Modeling of Exposed Slag Eye in Continuous Casting Mold using Euler-Euler Approach" - Vakhrushev A., Kharicha A., Wu M., Ludwig A., Nitzl G., Tang Y., Hackl G., Watzinger J., Rodrigues C.: 5th Int. Conf. on Adv. Solid. Proc. (ICASP-5) combined with 5th Int. Symp. on Cutting Edge of Comp. Sim. of Solid., Cast. and Refining, Salzburg, Austria, IOP Conf. Series: Mater. Sci. & Eng., 529 (2019) 012081.DOI:10.1088/1757-899X/529/1/012081

"On modelling viscoplastic behaviour of the solidifying shell in the funnel-type continuous casting mold" - Liu Z., Vakhrushev A., Wu M., Karimi-Sibaki E., Kharicha A., Ludwig A., Li B.: Metals 8 (2018) 609:1-4. DOI:10.3390/met8080609

"Effect of an Electrically-Conducting Wall on Transient Magnetohydrodynamic Flow in a Continuous-Casting Mold with an Electromagnetic Brake" - Vakhrushev A., Wu M., Ludwig A., Nitzl G., Tang Y., Hackl G., Wincor R.: Steel Res. Int. 87 (2016) 1600276:1-13.

"A Water Experiment Benchmark to Evaluate Numerical Models for the Motion of Particles in Continuous Casting Tundish" - Wu M., Vakhrushev A., Ludwig A., Kharicha A.: IOP Conf. Series: Materials Science and Engineering (ICASP-4) 117 (2016) 012045

"Influence of forced convection on solidification and remelting in the developing mushy zone" - Vakhrushev A., Wu M., Ludwig A., Tang Y., Hackl G., Nitzl G.: Metall. Mater. Trans. B., 45 (2014) 1024-37.

“Numerical investigation of shell formation in thin slab casting of funnel-type mould”

see also our Topic Related Publications